In many warehouses, these quality checks are still registered on a paper sheet. The (un)loaders are checking boxes on a clipboard with a pencil, or filling in values such as degrees Celsius. Why are they still doing this with pen and paper? Firstly, in most cases it concerns a significant number of check points. Secondly, because it is not always easier to do it with a scanner. Keyboards are really small and, especially in a cold store, the gloves or cold hands do not improve the fine motor skills.

These quality checks then need to be copied manually in Microsoft Dynamics’ document attribute sets, or in any other WMS used. Also, do not forget to take pictures. Your customers or clients demand proof. This can help you as well, by the way. These pictures need to be transferred from the camera to the order or the ride. You might feel it coming: this entire process can go a lot faster.

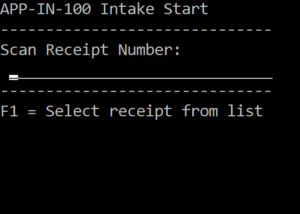

Example Telnet Scanning

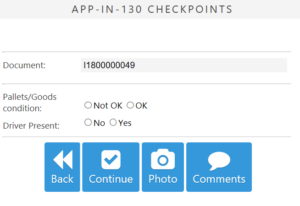

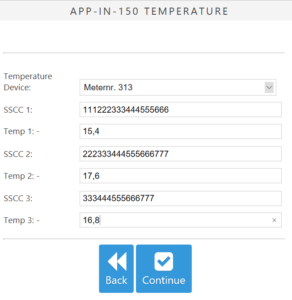

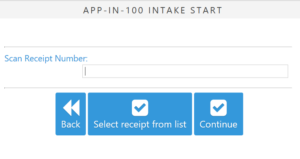

HTML5 Scanning uses the same functions as regular scanning en consists of the same scan function as the classic method. This way, Boltrics can easily configurate these processes based on proven technology. HTML5 distinguishes itself especially from the classic scan function in the following situations:

- Quality checks with many checkpoints;

- Employers need to take pictures and add these to a document;

- A truck driver needs to sign a document.

– The signature can be drawn on the touchscreen and can be added as an image.

No matter how you designed your logistics processes, Boltrics has a fitting scan solution for any situation. No more pen and paper, no more doctors’ handwriting, and double registration is in the past. Contact us and together, we will determine how your processes can be optimized.